Attenuation Material Guide

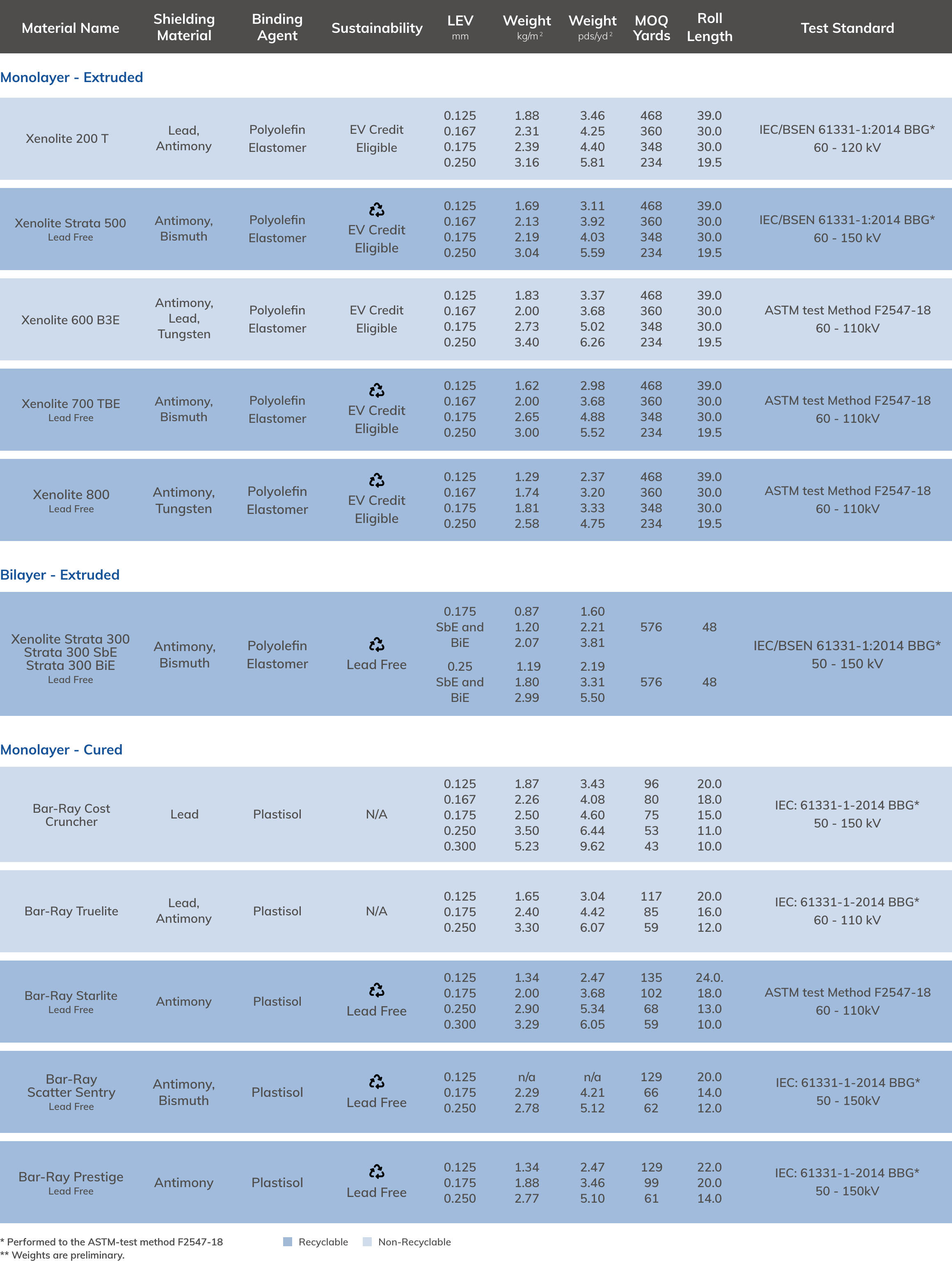

Burlington Medical is on a mission to provide you with the most effective attenuation material available. We offer different types of material with exceptional properties. All protective materials are offered in varying thicknesses to offer the best options to fit your needs.

Attenuation Material Guide

Bar-Ray Die Cut Curtains and Raw Material Guide

|

K-EDGE TECHNOLOGY |

COMBINED WITH ADVANCED POLYMER TECHNOLOGY |

ENVIRONMENTAL BENEFITS |

|

The lighter weight (lead-vinyl is 32% heavier) results from the use of the two attenuating elements, where the antimony provides more efficient attenuation of that portion of the photon spectrum below the K-edge window of lead (35 88 keV), comple-mented by the higher Z element tungsten, which is more efficient for stopping higher energy radiation (02 69 keV), and also covers the K-edge window of antimony (< 35 keV).

|

The attenuating elements, in fine powder form, are supported, encapsulated and homogeneously distributed in a tough-but flexible, high-tech plasticized Dow elastomer matrix. This Dow-DuPont developed elastomer carrier was selected in 2012 after 3 year’s R&D as having the best balance of toughness, flexibility, durability and cracking resistance, and is more commonly used for flexing components (e.g, running shoes, wire and cable).

|

The lead-free material is not “cross-linked” (or “cured”) and is therefore fully recyclable, and thermally re-processable, or may be disposed of as a non-hazardous, non-toxic waste, in municipal landfills.

|